Most plastic comes from fossil oil, but recycling it has rarely made economic sense, until now. Corsair uses advanced pyrolysis technology to turn plastic waste.

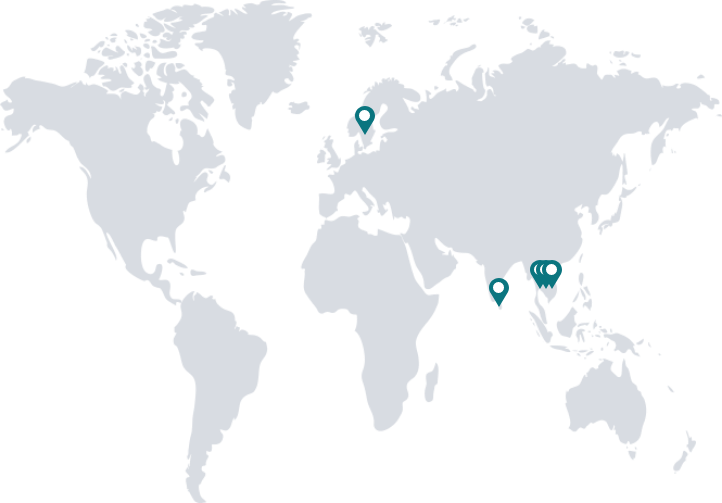

Corsair’s first pyrolysis facility and one of the company’s core operational hubs.

Bangkok 1 houses multiple pyrolysis units and supports continuous production of high-quality pyrolysis oil for our industrial partners.

The facility also serves as an active demonstration site for Corsair’s technologies and provides training for new operational teams.

An expanded production site featuring additional pyrolysis units and processing systems.

Bangkok 2 increases Corsair’s capacity to convert plastic waste into valuable recycled outputs while supporting ongoing R&D and operational scaling.

Corsair’s newest Thai facility, currently under development.

Bangkok 3 will further strengthen our production capacity and serve as a key driver in meeting regional demand for high-quality chemically recycled plastic.

Corsair’s first European facility, located in Jämsä.

Kaipola marks Corsair’s expansion into Europe, with operational pyrolysis units producing high-quality oil from plastic waste.

The facility plays a key role in European collaborations, technology development, and future growth across the continent.large-scale landfill management and plastic waste processing operation in partnership with the Municipality of Wang Nam Yen.

The Sa Kaeo site enables daily recovery, sorting, and processing of significant volumes of plastic waste, ensuring that plastic waste raw material is diverted from the landfill and transformed into feedstock for Corsair’s pyrolysis operations.

Corsair’s first facility in South Asia, launched through a strategic joint venture with LOLC.

Welisara will house Sri Lanka’s first advanced plastic waste chemical recycling operation, bringing Corsair’s technology and operations to an entirely new region and supporting national goals for sustainable waste management.

Corsair’s Research & Development facility at the Green Chemistry Campus in Bergen op Zoom serves as the company’s European innovation hub and the centerpiece of the C-RECYCLE Project—a pioneering initiative supported by the European Union’s Just Transition Fund.

Corsair’s first pyrolysis facility and one of the company’s core operational hubs.

Bangkok 1 houses multiple pyrolysis units and supports continuous production of high-quality pyrolysis oil for our industrial partners.

The facility also serves as an active demonstration site for Corsair’s technologies and provides training for new operational teams.

An expanded production site featuring additional pyrolysis units and processing systems.

Bangkok 2 increases Corsair’s capacity to convert plastic waste into valuable recycled outputs while supporting ongoing R&D and operational scaling.

Corsair’s newest Thai facility, currently under development.

Bangkok 3 will further strengthen our production capacity and serve as a key driver in meeting regional demand for high-quality chemically recycled plastic.

Corsair’s first European facility, located in Jämsä.

Kaipola marks Corsair’s expansion into Europe, with operational pyrolysis units producing high-quality oil from plastic waste.

The facility plays a key role in European collaborations, technology development, and future growth across the continent.large-scale landfill management and plastic waste processing operation in partnership with the Municipality of Wang Nam Yen.

The Sa Kaeo site enables daily recovery, sorting, and processing of significant volumes of plastic waste, ensuring that plastic waste raw material is diverted from the landfill and transformed into feedstock for Corsair’s pyrolysis operations.

Corsair’s first facility in South Asia, launched through a strategic joint venture with LOLC.

Welisara will house Sri Lanka’s first advanced plastic waste chemical recycling operation, bringing Corsair’s technology and operations to an entirely new region and supporting national goals for sustainable waste management.

Corsair’s Research & Development facility at the Green Chemistry Campus in Bergen op Zoom serves as the company’s European innovation hub and the centerpiece of the C-RECYCLE Project—a pioneering initiative supported by the European Union’s Just Transition Fund.

7

4

100+

14

Corsair’s chemical recycling facilities are modular, typically equipped with 10 pyrolysis machines.

Plastic waste is primarily sourced from municipal waste streams and landfills, where it is first sorted and potentially cleaned before processing.

Additional feedstock comes from established waste collection centers that sort different types of plastic waste, as well as from dedicated collection points at hotels, shopping centers, apartment buildings, hospitals, schools, and other commercial facilities.

The prepared plastic is then processed through Corsair’s advanced pyrolysis system.

Corsair’s process is ISCC-certified and optimized for energy efficiency. Once the machines reach operating temperature, syngas produced during the reaction is reused to maintain heat in the system, significantly reducing the need for external fuel and lowering emissions.

While the facility still requires electricity for various operations, this internal energy loop improves overall efficiency and reduces the project’s environmental footprint.

High QUALITY The main output is high-quality pyrolysis oil, intended for use as a raw material in the production of new plastic, not as fuel, supporting a truly circular economy. The oil quality meets the strict standards of the petrochemical industry and has created strong demand among major industry players.

APPLICATIONS Residues from the process include a small amount of char and wastewater. The char can be sold for industrial applications, while the wastewater is treated, reused where possible, and managed in full compliance with environmental regulations.

12,000 tons per year Each Corsair facility is designed to process approximately 12,000 tons of plastic waste per year and is engineered for rapid replication in new locations.

In addition to its environmental impact, each

facility also creates 40–60 local jobs, contributing

to regional economic development.

We help companies and organisations

offset their plastic footprint.

In addition to its environmental impact, each

facility also creates 40–60 local jobs, contributing

to regional economic development.

We help companies, brands and organizations to offset their plastic waste footprint.